bursting strength tester principle|bursting strength tester pdf : distributor A Mullen (bursting) test is a specific test performed to measure the bursting strength of paper or paperboard. In a burst test according to the Mullen principle , the paper sample is placed between two ring-like clamps, and a hydraulic pressure is used to inflate a rubber diaphragm, which expands against the sample stretching it.

WEB21 de nov. de 2023 · Human resource management, or HRM, involves coordinating, managing, and allocating human capital, or employees, in ways that move an organization’s goals forward. HRM focuses on investing in employees, ensuring their safety, and managing all aspects of staffing from hiring to compensation and development.

{plog:ftitle_list}

Para ver o resultado de ontem basta clicar na seta localizada na lateral da tabela que exibe os números sorteados. Jogo do Bicho Caminho da Sorte (PE) Sorteio .

how to calculate bursting factor

Package Vertical Steam Boiler —50L traders

bursting strength tester price

The best testing instrument which is used to measure the bursting strength of the papers and packaging products is the “Bursting Strength Tester”. The instrument creates sufficient hydraulic load under the rubber diaphragm in a specific area of the test specimen.Textile Learner is a reference guide for textile engineering. It helps to update .The working principle of Bursting Strength Tester is hydraulic pressure. The testing machine comes with rubber diaphragm and a digital readout of pressure with a peak hold facility. The hydraulic pressure is applied through a rubber .

Operational Principle: Bursting strength tester adopts signal transmission pressure, sample rupture automatically retain maximum fracture strength. The test piece is placed on the rubber mold, and is clamped by the clamping piece, and then the pressure is uniformly applied, so that the test piece and the adhesive film are free to bulge together . 3. Cost-savings: By using a bursting strength tester, you can avoid the damage of the products while transporting, hence, saves a lot of cost. Know more about Bursting Strength Tester. A bursting strength tester is a machine that is used to test the strength of materials such as paper, cardboard, and fabric.A Mullen (bursting) test is a specific test performed to measure the bursting strength of paper or paperboard. In a burst test according to the Mullen principle , the paper sample is placed between two ring-like clamps, and a hydraulic pressure is used to inflate a rubber diaphragm, which expands against the sample stretching it.

Bursting Strength Tester is used for testing fabric bursting strength and expansion such as knitted fabrics, non-woven fabrics, leather etc. skip to Main Content +86-551-68 105003 [email protected] . Basic principles of bursting performance testing (1) Steel ball method: A sample of a certain area is clamped in a circular sample clamp on a . Understanding Textile Bursting Strength Testing. Principles and Methods. At its core, bursting strength testing involves the application of hydraulic or pneumatic pressure to a fabric sample until it ruptures. The force required to achieve this rupture serves as a measure of the fabric’s bursting strength. Various testing methods exist .

Cap Torque Tester traders

In this blog, we are going to discuss brief information about the Presto bursting strength tester and the working principle of the Presto bursting strength tester. So, let us get started! So, let .This test, also known as a Mullen Burst Test, is one of the most common material properties test required by carriers and governments. Bursting Strength testing basically measures the force required to puncture through a corrugated board. This strength comes from various factors, including the thickness of the paper liner layers, the narrowness of the flutes, and the layers of .Introducing our state-of-the-art Bursting Strength Tester, a top-tier bursting strength machine designed for precision and reliability. This advanced burst testing machine is perfect for accurately determining the bursting strength of various materials, ensuring compliance with international standards such as ISO 2758, 2759, 2559, 3303, 3689, BS 3424, 3137, ASTM .TAPPI T 807, Bursting strength of linerboard, Test Method [6] TAPPI T 810, Bursting strength of corrugated board, Test Method [7] TAPPI T 1200, Interlaboratory evaluation of test methods to determine TAPPI repeatability and reproducibility [8] Brauns O., Danielsson E., Jordansson L., Svensk Paperstidning 23 867 (1954) 1) [9]

The HydroBurst Bursting Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the burst strength and expansion of materials. Skip to content. Home; . The principle of the hydraulic bursting strength test is: that a specimen is clamped on an extendable diaphragm. Liquid pressure is applied under the diaphragm.The working principle of a bursting strength tester involves applying increasing pressure to a small area of a material, such as paper or cardboard, until it bursts. This process begins by securely clamping the material in place within the tester. Then, a hydraulic or pneumatic system gradually increases the pressure on the material. Bursting strength tests are typically performed on knit or stretchy fabrics that are unsuitable for tensile strength testing. But it can also be applicable to test materials like woven or nonwoven fabrics, packaging cardboards, papers, etc. Principle Of Bursting Strength Tester: Bursting strength of fabric is measured by bursting strength tester.

Burst strength or bursting strength is an important physical indicator of the quality or durability of a knitted fabric. Fabric Bursting Strength Test Method 1 Hydraulic Method. The testing principle of the hydraulic method is, a certain area of the specimen is clamped on the extendable diaphragm, and liquid pressure is applied under the diaphragm.

Diaphragm bursting test. Ball bursting test. 1. Diaphragm Method: A is clamped over an expandable diaphragm. The diaphragm is expanded by fluid pressure to the point of specimen rupture. The difference .

Fabric Pneumatic Bursting Tester is applied to determine the bursting pressure of fabrics using the pneumatic test method, including knits, woven fabric, non-woven fabric, laminated fabric, and other craft-made fabric. Fabric Pneumatic .

Bursting Strength Testing Machine . It measures the bursting strength by applying hydraulic pressure through a rubber diaphragm on a circular area of the sample of the corrugated board under test. A digital indicator is used to measure the force needed to burst the board. It ranges from 0 to 40 kg/ square cm.

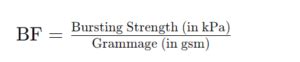

To operate this testing instrument, we have mentioned several steps below: you can know more about the bursting strength tester principle. When you start with the machine operating process, then .Bursting strength: Bursting strength is expressed as the maximum uniformly distributed pressure, applied at right angles to its surface, that a single sample piece can withstand under test conditions. The Burst index is the bursting strength divided by the grammage (ISO 2758-2001). Bursting strength compensated: The bursting strength value with .4 Principle A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free to bulge with the diaphragm. Hydraulic fluid is pumped at a constant rate, bulging the diaphragm until the test piece ruptures. The bursting strength of the test piece is the maximum value of the applied hydraulic pressure. 5 Apparatus The working principle of a bursting strength tester revolves around the application of hydraulic or pneumatic pressure to a sample until it bursts, thereby measuring its resistance to rupture.

Bursting strength is the force required to burst or rupture the material under testing. Bursting strength of test specimen is expressed in terms of Kg/cm². It is measured by giving hydraulic pressure through a rubber diaphragm on the test specimen. www.prestogroup.com Top View Side View Front View 600 mm 600 mm 450 mm 540 mm

The Bursting Strength Tester is an essential tool for any manufacturer looking to ensure the quality and durability of their materials. The digital model offered by Presto Group, with its advanced .4 Principle A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free to bulge with the diaphragm. Hydraulic fluid is pumped at a constant rate, bulging the diaphragm until the test piece ruptures. The bursting strength of the test piece is the maximum value of the applied hydraulic pressure. Overall, the test principle of ISO 13938-1:2019 is focused on accurately assessing the bursting strength of textiles using hydraulic or pneumatic pressure. By following standardized procedures and guidelines, manufacturers can ensure the quality and performance of their textile products, meeting the expectations of consumers and regulatory .

The working principle of Bursting Strength Tester Machine is based on applying a controlled pressure to a sample until it bursts. The pressure can be applied by using a rubber diaphragm or a steel .Bursting strength is the force required to burst or rupture the material under testing. Bursting strength of test specimen is expressed in terms of Kg/cm². It is measured by giving hydraulic pressure through a rubber diaphragm on the test specimen. www.prestogroup.com Top View Side View Front View 600 mm 600 mm 450 mm 540 mm

webMICRO SX-777AIR MA-808X Audio Union ¥548,000 21% Jun 30, 2023. Micro micro SX-777Air / RP-5070 Belt Drive Turntable belt Drive turntable . made of gold air pump attaching (1245402) Yahoo Auctions Auction bid. ¥649,800 May 13, 2022. **NEW BELT**Micro Seiki SX777 SX 777 AIR Turntable Belt Bonanza $19 14% Feb 8, 2021.

bursting strength tester principle|bursting strength tester pdf